Understanding PPR Valves: The Basics

PPR valves are specialized control devices used in piping systems to regulate the flow of fluids, primarily water. Unlike traditional metal valves, which can rust over time, PPR valves are crafted from a thermoplastic material that’s lightweight yet incredibly strong. This makes them ideal for hot and cold water distribution, where temperatures can fluctuate without compromising the valve’s integrity.

Key Features of PPR Valves

One of the standout attributes of a PPR valve is its chemical resistance. It doesn’t react with most substances found in household or industrial water, ensuring purity and safety. Additionally, these valves have smooth inner surfaces that minimize friction, leading to better flow rates and reduced energy consumption in pumping systems.

Durability and Longevity

In harsh environments, such as those with high mineral content in water, PPR valves excel by preventing buildup that could clog or damage the system. Users often report lifespans exceeding 50 years under normal conditions, far outpacing many alternatives.

Eco-Friendly Aspects

Being recyclable and free from harmful toxins, PPR valves align with green building practices. They contribute to sustainable construction by reducing the need for frequent replacements and lowering overall material waste.

If you’re interested in exploring more about sustainable plumbing options, check out our internal guide on eco-friendly pipe fittings.

Types of PPR Valves and Their Applications

PPR valves come in various designs to suit different needs, from simple shut-off mechanisms to more complex flow regulators. Understanding these types helps in making informed decisions for your specific project.

Ball Valves: Versatile and Reliable

Ball valves are among the most common PPR valve types, featuring a spherical disc that rotates to open or close the flow. They’re perfect for quick on-off control in water lines.

PPR Valve 3/4 Inch Variants

For medium-sized pipes, the PPR valve 3/4 inch size is particularly popular in home plumbing setups like showers or sinks. It offers a balance between flow capacity and ease of installation, ensuring minimal pressure drop.

Gate Valves: For Full Flow Control

Gate valves use a sliding gate to block or allow passage, ideal for applications where you need unrestricted flow when open. They’re commonly used in main water supply lines.

Socket-End Valves: Seamless Integration

The PPR valve socket design allows for heat fusion welding directly to pipes, creating a joint that’s as strong as the pipe itself. This eliminates leaks at connection points, a common issue with threaded alternatives. If you’re dealing with underground or concealed installations, opting for a PPR valve socket can save significant maintenance headaches down the line.

For detailed specs on socket fittings, visit our PPR socket products page.

Factors Influencing PPR Valve Price

Pricing for PPR valves can vary based on several elements, but understanding these can help you budget effectively without sacrificing quality.

Material Quality and Manufacturing Standards

Higher-grade polypropylene and precision engineering command a premium, but they pay off in reliability. At Zhejiang HONGKE Valves factory, we prioritize using certified materials that meet international standards, which influences the PPR valve price but ensures value.

Size and Customization Options

Larger diameters or custom features, like the PPR valve 3/4 with brass inserts for added strength, might increase costs slightly. However, bulk purchases often bring down the per-unit PPR valve price, making it economical for contractors.

Market Trends and Supplier Reliability

Global supply chain factors can affect pricing, but choosing a direct manufacturer like HONGKE helps avoid markups from middlemen. For authoritative insights on plastic valve standards, refer to the ISO technical committee on plastics.

In general, expect a competitive PPR valve price range starting from a few dollars per unit for standard models, scaling up based on complexity.

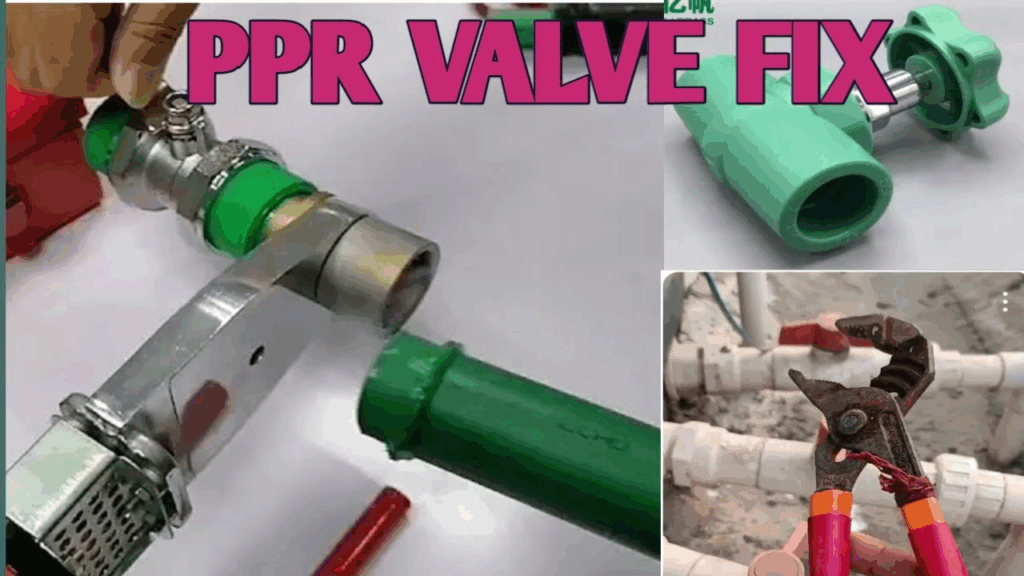

Installation Guide for PPR Valves

Proper installation is crucial to maximize the benefits of your PPR valve. While it’s straightforward, following best practices ensures a leak-free system.

Preparation Steps

Before starting, gather tools like a heat fusion machine, pipe cutters, and measuring tape. Ensure all surfaces are clean and dry.

Cutting and Fitting

Measure twice and cut once. For a PPR valve socket, align the ends precisely for fusion. Heat both the valve and pipe to the recommended temperature—usually around 260°C—for a secure bond.

Common Installation Scenarios

In residential setups, installing a PPR valve near fixtures allows easy shut-off for repairs. For commercial use, integrate them into manifolds for zoned control.

Troubleshooting Tips

If you encounter issues like uneven fusion, it might be due to inconsistent heating. Always test the system under pressure post-installation to catch any weaknesses early.

For more hands-on advice, browse our installation resources.

Why Choose Zhejiang HONGKE Valves Factory for Your PPR Needs

Located in Zhejiang, China, HONGKE Valves has been a cornerstone in the valve manufacturing industry since 2008. While we started with PVC products, our expansion into PPR valves reflects our commitment to innovation and meeting diverse market demands. Our factory employs state-of-the-art machinery and rigorous quality control to produce PPR valves that are not only durable but also tailored to global standards.

Commitment to Quality

Every PPR valve undergoes multiple inspections, from raw material testing to final pressure trials. This dedication ensures that when you install a HONGKE PPR valve, you’re investing in peace of mind.

Customer-Centric Approach

We offer customization options, competitive PPR valve price structures, and prompt shipping. Our team is always ready to assist with technical queries, making us a preferred partner for plumbers and builders worldwide.

Real-World Applications and Testimonials

In projects ranging from high-rise apartments to agricultural irrigation, HONGKE PPR valves have proven their worth. One contractor shared, “Switching to HONGKE’s PPR valve socket fittings reduced our leak incidents by 80%, saving time and money.”

Maintenance and Care for Long-Lasting Performance

To keep your PPR valve functioning optimally, regular maintenance is key. Periodically check for signs of wear, especially in high-traffic areas.

Cleaning Procedures

Use mild detergents for external cleaning; avoid abrasive materials that could scratch the surface. For internal buildup, flushing the system with clean water suffices in most cases.

When to Replace

If you notice reduced flow or unusual noises, it might be time for a new PPR valve. Proactive replacement prevents larger system failures.

Comparing PPR Valves to Other Materials

While metal valves like brass or steel have their places, PPR valves offer advantages in weight, cost, and corrosion resistance. For instance, in acidic water environments, PPR outperforms copper without the risk of pitting.

Cost-Benefit Analysis

Initial PPR valve price might be similar to PVC, but the extended lifespan and lower maintenance costs tip the scales in favor of PPR for long-term projects.

Future Trends in PPR Valve Technology

The industry is moving towards smarter valves with integrated sensors for real-time monitoring. At HONGKE, we’re exploring these advancements to bring even more efficient solutions to market.

In conclusion, whether you’re outfitting a new home or retrofitting an industrial setup, a well-chosen PPR valve can elevate your system’s performance. With options like the versatile PPR valve 3/4 and reliable PPR valve socket designs, Zhejiang HONGKE Valves factory stands ready to supply your needs at a fair PPR valve price. Contact us today to discuss how we can support your next project.